+1 (310) 953-5153(texto)

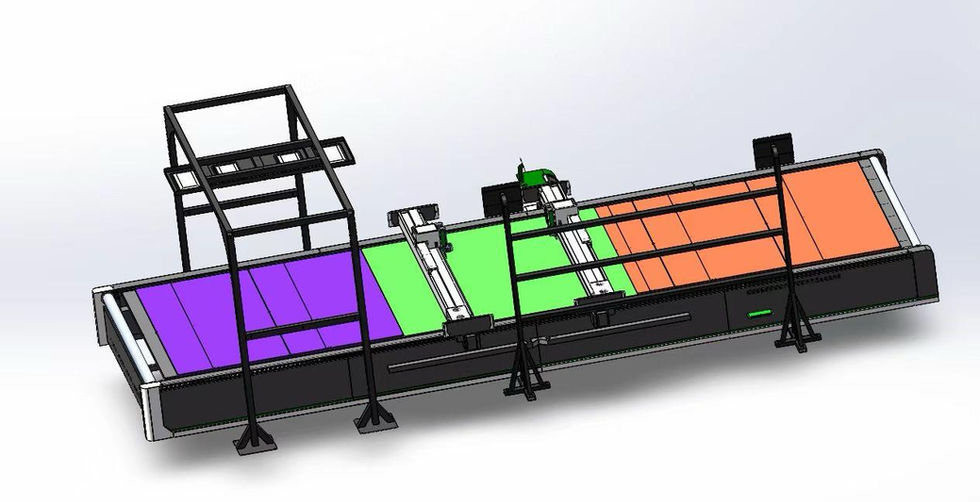

Standard leather cutter MM11/MMT-ZP1860 S

The MMTCNC cutting machine features an automatic platform compensation system that adjusts the knife depth automatically, removing the need for manual platform adjustment.

It uses advanced four-axis CNC cutting technology (X, Y, Z, T axes). The X and Y axes use linear guide rails and digital servo motors for smooth movement. The Z axis uses a ball screw and servo motor for fast, precise up-down positioning. The T axis controls the knife, automatically tracking line paths using a high-speed Swiss servo motor.

All four axes move together with physical interpolation, providing high accuracy, speed, and flexibility. The simple interface is easy to learn and operate.

The added T axis enables precise cutting of complex shapes and flexible materials—things standard blades can't do. The knife can move up to 18,000 times per minute for smooth, clean cuts.

The system also includes automatic switching between pen, half knife, full knife, and press wheel. Users can set knife pressure for different materials, completing all drawing and cutting tasks in one go.

Cantidad